FAQ

IMIBUZO EBUZWA QHO

Iimpazamo zamanqanaba amathathu e-asynchronous motors zinokuhlulwa ngokubanzi zibe ziinxalenye ezimbini: iimpazamo zombane kunye neempazamo zomatshini.

Iimpazamo zoomatshini ziquka: iibheringi ezingafanelekanga okanye ezonakalisiweyo, imikhono yokuthwala, i-oil caps, i-end caps, iifeni, izihlalo kunye nezinye iindawo, kunye nokugqoka kunye nokukrazula kweengxenye ze-shaft.Iimpazamo zombane zibandakanya ikakhulu: i-stator kunye ne-rotor winding breakage, phakathi kokujika (isigaba), ukuya emhlabeni, njl.

I-stator kunye ne-rotor zenziwe ngamashiti ensimbi ye-silicon edibeneyo kwaye ziyinxalenye yesekethe yemagnethi yemoto.Umonakalo kunye nokuguqulwa kwe-stator kunye ne-rotor cores zibangelwa ikakhulu ngale miba ilandelayo.

(1) Ukuguga okugqithisileyo okanye ukudityaniswa kakubi, okukhokelela kwi-stator kunye ne-rotor rubbing, kubangela umonakalo ongundoqo womphezulu, obangela ukuba isekethe emfutshane phakathi kwamaqhekeza entsimbi ye-silicon, ikhulise ilahleko yentsimbi yemoto, okwenza ubushushu bemoto bunyuke kakhulu. eliphezulu, xa isicelo ifayile ecikizekileyo kunye nezinye izixhobo ukususa Burr, ukuphelisa intsimbi yesilicon iqhekeza uqhagamshelwano olufutshane, ucoce kwaye uqatywe ngepeyinti insulating, kunye ukufudumeza nokomisa.

2

(3) Undoqo okanye amazinyo atshiswe ngenxa yobushushu obuphezulu obuveliswa kukumisa ukujikajika.Isixhobo esifana ne-chisel okanye i-scraper singasetyenziselwa ukususa izinto ezityhidiweyo kwaye zomise ngepeyinti ye-insulating.

(4) Ukudibanisa phakathi kwengundoqo kunye nesiseko somatshini kukhululekile, kwaye izikrufu zangaphambili zokubeka zingaqiniswa.Ukuba izikrufu zokubeka aziphumeleli, phinda ugrumbe imingxuma yokumisa kwaye ucofe kwisiseko somatshini, qinisa izikrufu zokubeka.

Xa i-rolling bear imfutshane kwioli, isandi samathambo siya kuvakala.Ukuba isandi esiqhubekayo sokulandela sivakala, sisenokuba kukugqabhuka kweringi yentsimbi.Ukuba ukuthwala kuxutywe nesanti kunye nezinye i-debris okanye iindawo ezithwalayo zigugile, ziya kuvelisa ingxolo encinci.Khangela emva kokuqhaqha: jonga kuqala umzimba ojikelezayo webheringi, ngaphakathi nangaphandle kwentsimbi yentsimbi ngomonakalo, umhlwa, amanxeba, njl. ngesinye isandla sakho, ukuba ukuthwala kulungile, umsesane wentsimbi yangaphandle kufuneka ujikeleze ngokutyibilikayo, akukho kungcangcazela kunye nokubonakala kwe-jamming kwi-rotation, akukho ukuhlehla kwentsimbi yangaphandle emva kokumisa, ngaphandle koko ukuthwala akusayi kusetyenziswa.Isandla sasekhohlo sincamathele kumsesane ongaphandle, isandla sasekunene sicinezela umsesane ongaphakathi wentsimbi, sinyanzele ukutyhala macala onke, ukuba uziva ukhululekile kakhulu xa utyhala, kukunxitywa okunzulu.

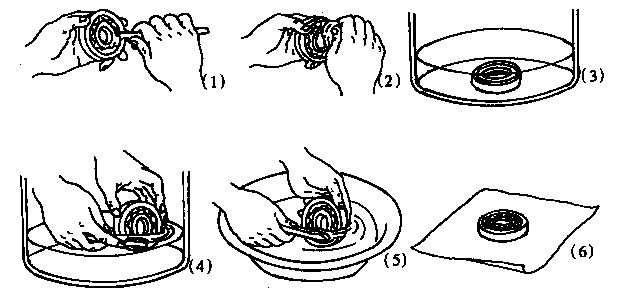

Ukulungiswa kwempazamo ethwele umhlwa amabala akhoyo akhoyo 00 sandpaper yosula, kwaye emva koko kwi-petroli yokucoca;ethwele iintanda, ngaphakathi nangaphandle kweringi eyaphukileyo okanye ethwele ukuguga okugqithisileyo, kufuneka itshintshwe ngeebheringi ezintsha.Xa utshintsha ibheringi entsha, sebenzisa uhlobo olufanayo lwebheringi nolokuqala.Ukuthwala ukucoca kunye ne-refueling.

Ukuthwala inkqubo yokucoca: qale uhlambe ioli yenkunkuma ebusweni bebhola yensimbi;sula ioli yenkunkuma eseleyo ngelaphu lomqhaphu;Emva koko yithi nkxu ibhere kwipetroli kwaye ukhuhle ibhola yentsimbi ngebrashi;emva koko uhlambulule ibheringi ngepetroli ecocekileyo;ekugqibeleni ubeke ukuthwala ephepheni ukwenza i-petroli ibe ngumphunga kwaye yome.

Inkqubo yokugcoba i-greasing: Ukukhethwa kwegrisi ejikelezayo, eyona nto ithathelwa ingqalelo yimeko yokusebenza yokuthwala, njengokusetyenziswa kwendawo (emanzi okanye eyomileyo), ukushisa okusebenzayo kunye nesantya semoto.Umthamo wegrisi akufanele udlule i-2/3 yomthamo wegumbi lokuthwala.

Xa ukongeza ioli yokuthambisa kwi-bearing, ioli kufuneka icinezelwe ukusuka kwelinye icala lokuthwala kwaye emva koko i-oyile engaphezulu kufuneka ikhutshwe ngobumnene ngomnwe, nje ngokuba ioli inokongezwa ide ikwazi ukutywina ibhola yentsimbi ngokuthe ngqo. .Xa ufaka ioli yokuthambisa kwikhava yokuthwala, ungafaki kakhulu, malunga ne-60-70% yanele.

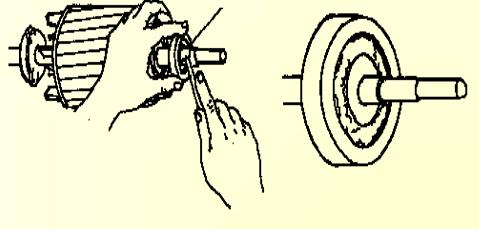

(1) ukugoba kweshaft ukuba igophe alikho likhulu, inokulungiswa ngokusila ishaft ububanzi, indlela yokutyibilika yeringi;ukuba i-bend ingaphezulu kwe-0.2mm, i-shaft inokufakwa phantsi kwe-press, kwi-shot egoba ukulungiswa koxinzelelo, ukulungiswa kwendawo ye-shaft kunye ne-lathe cutting cutting;njengokugoba kukhulu kakhulu kufuneka kutshintshwe ishaft entsha.

2ukugqoka ngaphezulu, kunokuba entanyeni ye-welding yokugqithisa, kwaye emva koko kwi-lathe yokusika kunye nokugaya;ukuba ijenali ukunxiba inkulu kakhulu, kwakhona kwijenali ka 2-3mm, uze ujike umkhono ngelixa kushushu iseti kwijenali, kwaye ke ujike kubungakanani obufunekayo.

Ukuqhekeka kweshafti okanye ubunzulu obunqamlezileyo bokuqhekeka kweshafti akudluli kwi-10% -15% yedayamitha yeshafti, iintanda ze-longitudinal azidluli kwi-10% yobude beshafti, zinokulungiswa ngendlela ye-welding eyalekayo, kwaye emva koko ujikeke kakuhle kubungakanani obufunekayo.Ukuba i-crack kwi-shaft iyingozi ngakumbi, i-shaft entsha iyafuneka.

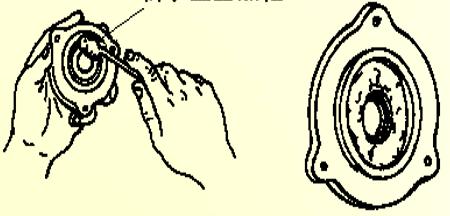

Ukuba kukho iintanda kwizindlu kunye nesigubungelo sokuphela, kufuneka zilungiswe ngokugqithiswa kwe-welding.Ukuba ukucocwa kwe-bearing bore kukhulu kakhulu, okubangela ukuba isigqubuthelo sokugqibela sikhululeke kakhulu, udonga lwe-bearing bore lunokutshatyalaliswa ngokulinganayo ngokusebenzisa i-punch, kwaye ke ukuthwala kunokufakwa kwi-cover cover, kunye neenjini. ngamandla amakhulu, ubungakanani obufunekayo bokuthwala bunokwenziwa ngoomatshini ngokufaka inlaying okanye iplating.

Isiseko sofakelo lweemoto asikho kwinqanaba.Inqanaba lesiseko semoto kwaye uyilungise ngokuqinileyo emva kokulinganisa isiseko.

Isixhobo asigxininisi kuqhagamshelo lwemoto.Lungisa kwakhona ukugxila.

I-rotor ye-motor ayilingani.I-Static okanye i-dynamic balancing ye-rotor.

I-pulley yebhanti okanye i-coupling ayilingani.Ipuli okanye ukudibanisa ukulinganisa ukulinganisa.

I-rotor shaft intloko egobileyo okanye i-pulley eccentric.Ukulungelelanisa i-rotor shaft, misela i-pulley ngokuthe tye kwaye usethe isethi yokuguqulwa kwakhona.

Uxhulumaniso olungalunganga lwe-stator winding, isiphaluka esifutshane sengingqi okanye isiseko, okubangelwa ukungalungelelani kwesigaba sesithathu samanje kunye nokubangela ingxolo.

Umba wangaphandle okanye ukungabikho kweoli yokuthambisa ngaphakathi kwibheringi.Coca iibheringi kwaye utshintshe i-lubricant entsha ye-1/2-1/3 yegumbi lokuthwala.

Ukufuduka okukhululekile phakathi kwe-stator kunye nendlu okanye i-rotor core kunye ne-rotor shaft.Jonga imeko yokunxiba ye-fit, re-welding, processing.

I-Stator kunye ne-rotor ukuxutywa kobuxoki.Fumana indawo ephakamileyo ye-iron core, ukugaya ukucutshungulwa.

Ingxolo ye-electromagnetic ngexesha lokusebenza kwemoto.Kunzima ukuphelisa ngokulungisa.

| Iklasi ye-Insulation | Ubushushu.(℃) |

| Iklasi ye-Insulation | Ubushushu.(℃) |

| Y A E B | 90 105 120 130 | F H C | 155 180 >180 |

① i-viscosity ephantsi, umxholo oqinileyo kunye nokuntywiliselwa ngokulula.

② ukunyanga ngokukhawuleza, ukudibanisa okuqinileyo kunye nokuqina.

③ Iimpawu zombane eziphezulu, ukumelana nobushushu, ukuxhathisa ukufuma kunye nokuzinza kweekhemikhali.

a) I-shaft kunye ne-tile gap incinci kakhulu.

b) Ukuvuleka kwesinyi se-oyile esincinci kunye nokutya okungonelanga kwe-oyile.

c) ukushisa okuphezulu kweoli yokuthambisa.

d) Ukwenzakala kophando lwethayile kwishaft.

e) Ukungabuyi kakuhle kwe-oyile kunye nokutya okungonelanga kwe-oyile.